Brand Name: HANSEN

Model Number: WNS1-0.7-Y(Q), WNS1-1.0-Y(Q), WNS1-1.25-Y(Q)

Place of Origin: Henan, China

Description & Models

Full-auto Industrial Alcohol Fired Steam Boiler with Condenser

Boiler Model: WNS1-0.7-Y(Q), WNS1-1.0-Y(Q), WNS1-1.25-Y(Q)

Steam output: 1000KG/HR (940HP, 71BHP)

Rated working pressure: 7Bar, 10Bar, 12.5Bar

Rated steam temperature: 170℃, 184℃, 194℃

Alcohol consumption of 1000KG/HR Steam Boiler: Alcohol 116L/Hr

a. Energy Saving: WNS Series Industrial Alcohol Fired Steam Boiler adopting high quliaty low nitrogen split-type burner; pre-heat the air for burner, raise the furnace's temperature and increase combustion efficiency.

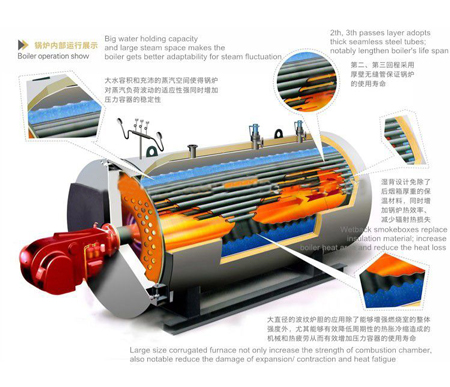

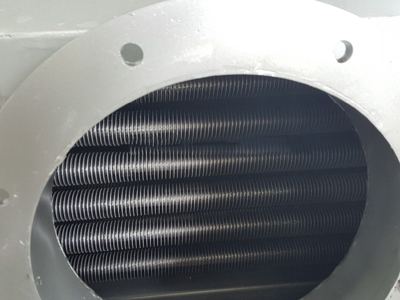

b. High Efficiency: WNS Series Industrial Alcohol Fired Steam Boiler has especial full wet-back and three passes design; adopting spirally corrugated fire tubes to increase boiler heating surface. Additional, it equiped with condensing economizer to full using the latent heat of waste smoke. Boiler's working efficiency can reach more than 95%.

c. Safe Operation: WNS Series Industrial Alcohol Fired Steam Boiler can automatically regulate the working pressure, water level; automatically burner igniting/ flameout, water shortage protect, overpressure protect.

d. Automatic Control: WNS Series Industrial Alcohol Fired Steam Boiler adopting advanced touch screen control cabinet and digital computer full automatic controller. The water feeding system controller can automatically regulate water feeding rate, make sure boiler's water stay on the standard water level. According to boiler's working pressure, burner controller can automatically regulate output power; the burner's output has one stage fire, two stages fire or three stages fire.

e. Convenience: WNS Series Industrial Alcohol Fired Steam Boiler which gets compact structure and openable front/back smoke boxes, manhole, handhole, platform ladder. Above designs are convenient for installation, maintenance.

Boiler Models

a. More Models of Industrial Alcohol Fired Steam Boiler.

b. 500kg/hr, 700kg/hr, 1000kg/hr, 1500kg/hr, 2000kg/hr, 3000kg/hr, 4000kg/hr, 6000kg/hr.

|

Full-auto Industrial Alcohol Fired Steam Boiler with Condenser |

||||||

|

Boiler Model |

WNS0.5-0.7-Y(Q) |

WNS0.7-0.7-Y(Q) |

WNS1-0.7-Y(Q) |

WNS1-1.0- Y(Q) |

WNS1.5-1.0-Y(Q) |

WNS2-1.0-Y(Q) |

|

Evaporation (Kg/hr) |

500 |

700 |

1000 |

1000 |

1500 |

2000 |

|

Pressure (Bar/ Mpa) |

7/ 0.7 |

7/ 0.7 |

7/ 0.7 |

10/ 1.0 |

10/ 1.0 |

10/ 1.0 |

|

Steam Temp (℃) |

170 |

170 |

170 |

184 |

184 |

184 |

|

Dimension (m) |

2.9*1.4*1.75 |

2.9*1.5*1.85 |

3.3*1.76*2.1 |

3.3*1.76*2.15 |

3.4*2.1*2.25 |

3.8*2.0*2.2 |

|

Weight (KG) |

3500 |

4150 |

4800 |

5300 |

5900 |

6800 |

|

Loading |

1*20'GP |

1*20'GP |

1*20'GP |

1*20'GP |

1*20'OT/ 40'HQ |

1*20'OT/ 40'HQ |

|

Structure |

Fire tubes, Three pass, Wet back |

|||||

|

Fuel Type |

Alcohol, Oil (diesel, waste oil), Gas (natural gas, LPG, etc.) |

|||||

|

Operation |

PLC automatically control the water level, burner combustion, fault protection, etc. |

|||||

|

Full-auto Industrial Alcohol Fired Steam Boiler with Condenser |

||||||

|

Boiler Model |

WNS2-1.25-Y(Q) |

WNS2-1.6-Y(Q) |

WNS3-1.25-Y(Q) |

WNS4-1.25-Y(Q) |

WNS4-1.6-Y(Q) |

WNS6-1.25-Y(Q) |

|

Evaporation (Kg/hr) |

2000 |

2000 |

3000 |

4000 |

4000 |

6000 |

|

Pressure (Bar/ Mpa) |

12.5/ 1.25 |

16/ 1.6 |

12.5/ 1.25 |

12.5/ 1.25 |

16/ 1.6 |

12.5/ 1.25 |

|

Steam Temp (℃) |

194 |

204 |

194 |

194 |

204 |

194 |

|

Dimension (m) |

3.8*2.0*2.35 |

3.8*2.15*2.4 |

4.3*2.1*2.55 |

4.58*2.3*2.65 |

4.58*2.4*2.75 |

5.3*2.4*2.7 |

|

Weight (KG) |

7200 |

7920 |

9100 |

12300 |

13100 |

16200 |

|

Loading |

1*20'OT/ 40'HQ |

1*20'OT/ 40'HQ |

1*40'HQ |

1*40'HQ |

1*20'OT & 20'GP |

1*20'OT & 20'GP |

|

Structure |

Fire tubes, Three pass, Wet back |

|||||

|

Fuel Type |

Alcohol, Oil (diesel, waste oil), Gas (natural gas, LPG, etc.) |

|||||

|

Operation |

PLC automatically control the water level, burner combustion, fault protection, etc. |

|||||

Finished Boilers

Exhaust Condenser

As we we know, after fuel consumption, the 140℃ exhaust gas contains lots of high temperatue water vapour, CO2, NOX, SO2 etc. If discharge the exhaust gas directly, will lose large amount of heat and pollute the environment. So, our boiler equipped Exhaust Gas Condenser to condense the water vapour in exhaust gas and reuse the latent heat.

Usually, the WNS boiler's thermal efficiency only can reach 85-91%. However, Exhaust Gas Condenser can observably reduce exhaust gas's temperature from 140℃ to 60℃, and increase 10% thermal efficiency, and save 10% fuel consumption. Last not the least, the condensate water can also dissolve the harmful gas in exhaust; and the boiler can re-use the condensate water for water supplement. Therefore, Exhaust Gas Condenser has important function for fuel saving/ water saving and environment protection.

Supply Scope

For quick delivery, we has new whole set of industrial alcohol fired steam boiler in stock. After getting the order, our company will finish the production in short time.

|

--Supply Scope-- |

|||

|

1, Boiler Body & Valves (China, HANSEN) |

2, Oil/ Gas Burner (Italy BALTUR/ RIELLO) |

3, Water Softener (USA, Fleck) |

4, Multi-stage Pump (China, CNP) |

|

5, PLC Control (China, RUNTECH) |

6, Steam Manifold (China, HANSEN) |

7, Chimney (China, HANSEN) |

8,Exhaust Gas Condenser (China, HANSEN) |

Our Service

Warranty Period

1, Free exchange within 24 Months for non-man-made damaged boiler main-body; and within 12months for non-man-made damaged boiler auxiliaries.

2, Long life technical service.

Installation Services

Option 1, Before the shipment, our company completes the installation and testing of boiler. After receiving the boiler, the user just connect the boiler to the pipe/ water/ electricity/ fuel.

Option 2, Our company provides the installation drawings and operation manuals; then user arranges the installation on their own. This service is free.

Fuel: Gas

User’s site: China

Model: WNS20-1.25-Y(Q)

Steam capacity: 20000kg/hr

Working pressure: 1.25Mpa

Application: vacation resort heating

Fuel: Gas

User’s site: Egypt

Model:WNS2-1.0-Y(Q),WNS0.5-1.0-Y(Q)

Steam capacity: 2000kg/hr, 500kg/hr

Working pressure: 1.0Mpa

Application: hotel laundry machines

Fuel: Gas

User’s site: Malaysia

Model: WNS6-1.25-Y(Q)

Steam capacity: 6000kg/hr

Working pressure: 1.25Mpa

Application: rubber production

Fuel: Diesel Oil

User’s site: Nigeria

Model: WNS1-1.0-Y(Q)

Steam capacity: 1000kg/hr

Working pressure: 1.0Mpa

Application: hotel building heating

Fuel: Diesel Oil

User’s site: Chile

Model: WNS1.5-1.0-Y(Q)

Steam capacity: 1500kg/hr

Working pressure: 1.0Mpa

Application: Beer brewing

Fuel: Diesel Oil

User’s site: Bangladesh

Model: WNS4-1.25-Y(Q)

Steam capacity: 4000kg/hr

Working pressure: 1.25Mpa

Application: Edible oil production

Factory Show

Factory area 120000 square meter; annual production capacity 3000 steam tons.

Mainly produce steam boiler, hot water boiler, hot air stove, thermal oil boiler, wood pressure treatment plant.

Grade B boiler manufacturer, ISO9001: 2000 certificate, honorary title HENAN TECHNOLOGY ENTERPRISE.

Clean and standard workshops, provides comfortable working environment than traditional companies. We have cleaning department, production supervision department, materials & new boiler storage department.

advanced manufacturing facilities make sure all productionprocesses goes smoothly with good quality.

such as hydraulic pressure bending machine, numerical control cutting, automatic submerged arc welding, semi automatic drilling machine, x-ray flaw detector, hydraulic pressure test device, automatic painting.

professional pre-sales/ after-sales, make you get quality products and judgmatical service. Please consulting our pre-sales for guiding buy. Any after-sale service please consulting our after-sales directly.

Business Certificate